Cold Cutting

We can make accurate 1mm wide cuts in steel of up to 200mm thick

Key features of Cold Cutting

NO DANGER OF EXPLOSION

Cutting without heat or spark

REDUCED EXCLUSION ZONE

No explosive or hot works of any kind reduces exclusion radius

REDUCED CLEAN UP

Blast media and swarf is contained within the water

LOW WASTE & NOISE PRODUCTION

Reduced waste and noise when compared to traditional cutting techniques

UNDERWATER APPLICATIONS

Horizontal, vertical and radial cuts can be achieved

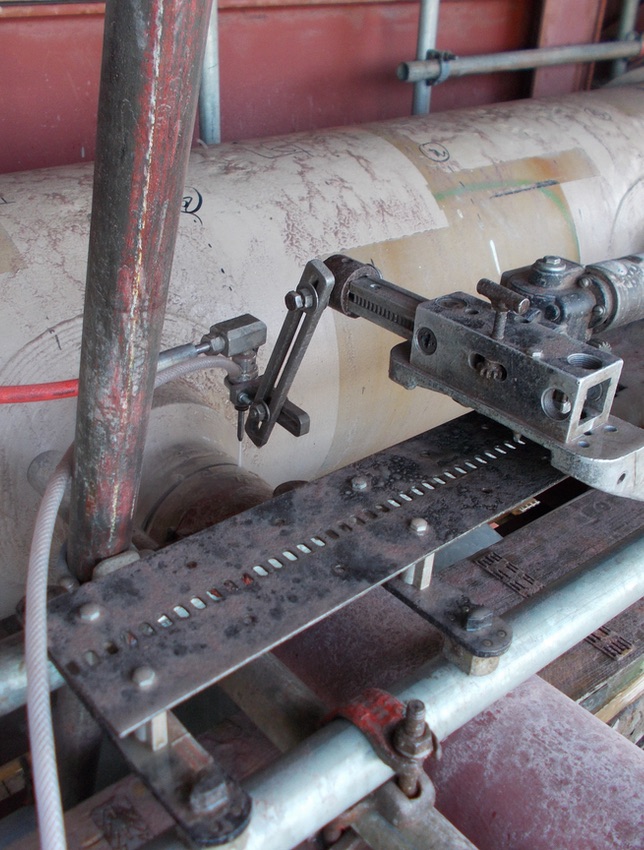

REMOTE CONTROL

Operator safely controls away from the work face

CUT COMPOSITE MATERIALS

Regardless of the type or thickness of the material, our water jets will cut it.

ACCURATE CUTS 1MM WIDE

The automated cutting carriage allows for precice, repeatable cuts

High pressure water jet cutting with abrasive

The process uses a fine ultra-high pressure water jet nozzle which entrains a small quantity of fine garnet as the abrasive media

Cold Cutting Applications

01

Decomissioning

Cold Cutting is a useful tool in the decomissioning of end of life plant equipment

02

Access

Cold cutting can be used to create access apetures in areas where ‘hot works’ would not be permitted

03

Stone Cutting

Cold Cutting stone reduces waste and improves portability