Finite Element Analysis (FEA) in Our Organization

Finite Element Analysis, commonly known as FEA, is a vital engineering and computational tool that plays a significant role in the core of our organization. FEA is a simulation technique used to analyze complex structures and systems by breaking them down into smaller, more manageable elements, known as finite elements, and applying mathematical models to understand their behavior under various conditions.

At our organization, FEA is a fundamental component of our engineering and design processes. We recognize the importance of utilizing this advanced technology to optimize our products and solutions in a wide range of industries. Here are some key ways in which FEA is integrated into our operations:

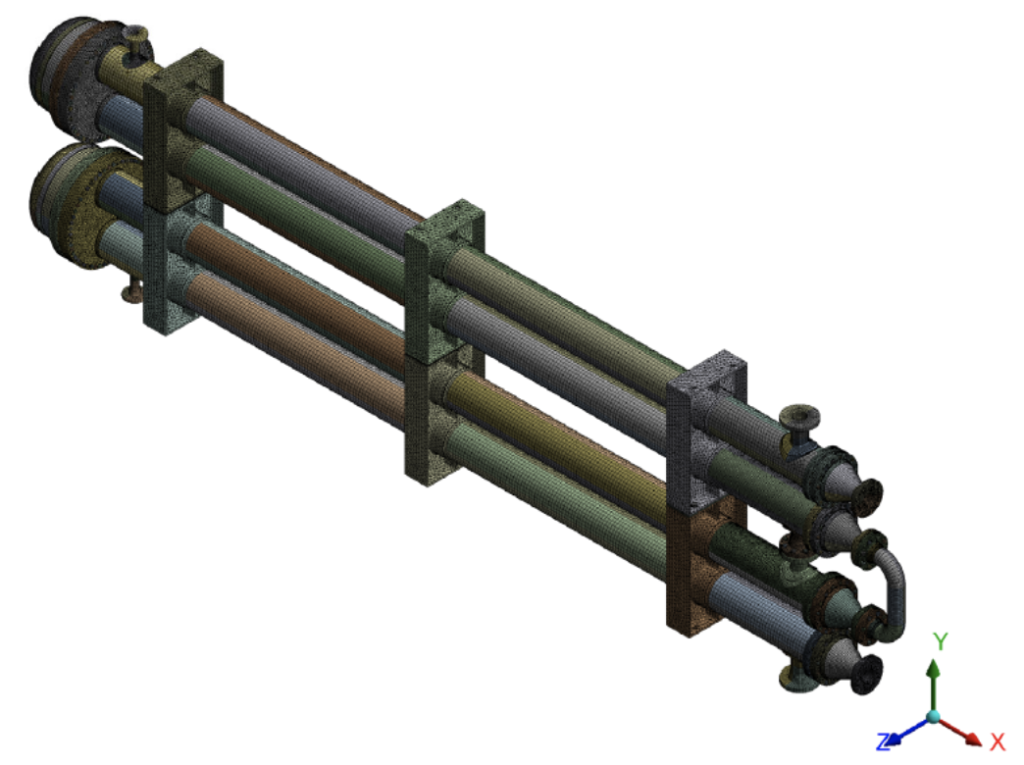

FEA for Hair Pin type Heat Exchanger.

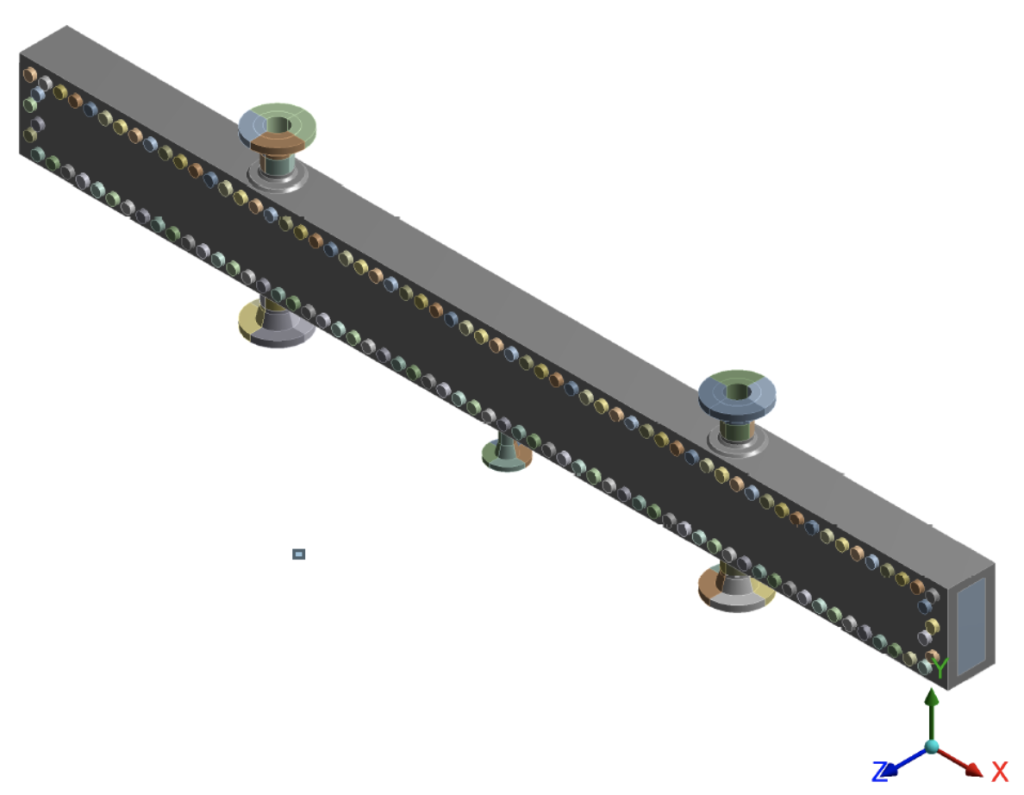

FEA for Air Cooled Heat Exchanger Header Box.

- 1. Product Design and Validation

FEA allows us to model and simulate the behavior of components and systems before physical prototypes are constructed. This not only accelerates the design process but also ensures that our products meet the highest standards of performance, safety, and reliability.

- 2. Structural Analysis

We employ FEA to assess the structural integrity of materials, components, and entire systems. This is particularly crucial in industries such as aerospace, automotive, and construction, where safety and durability are paramount.

- 3. Optimization

FEA enables us to optimize designs for weight, cost, and performance. By running simulations with different parameters, we can fine-tune our solutions to achieve the best possible outcomes.

- 4. Failure Analysis

When components or systems fail, FEA is a valuable tool for investigating the root causes. It helps us understand failure mechanisms and develop solutions to prevent future issues.

- 5. Customization

FEA allows us to tailor our solutions to meet specific customer requirements. By simulating different scenarios, we can create bespoke products that address unique challenges.

Finite Element Analysis (FEA) in Our Organization

Incorporating FEA into our organization's workflow is a testament to our commitment to delivering cutting-edge and dependable solutions to our clients. It empowers our engineering teams to make informed decisions, improve product performance, and enhance the overall quality of our offerings. As we continue to embrace technological advancements, FEA remains a cornerstone in our quest for excellence and innovation in various industries.